Welcome to TOSTA’s Blog

The TOSTA blog aims to share the prototyping and rapid manufacturing knowledge, experience and skills we have accumulated over the years.

UV Printing services

We provide high-quality metal parts Silk-screen Print services for each customer.

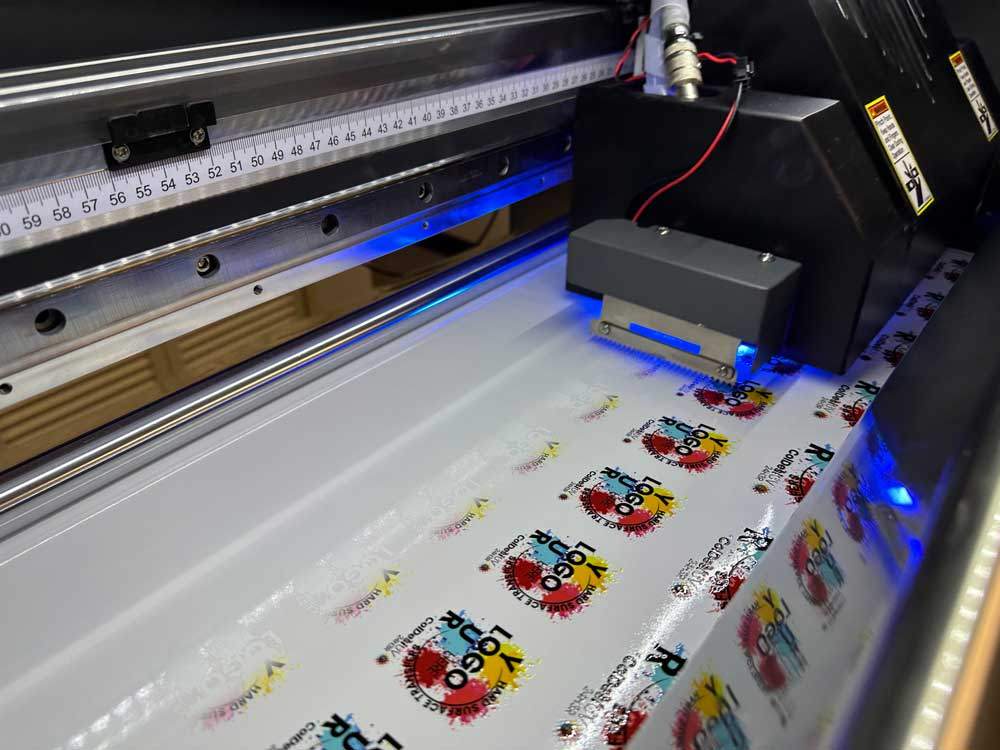

UV Printing Services

Industrial UV printers print digital images directly and print them directly onto a substrate. This technology has made it possible for decorators to print graphics on many different types of substrates that were not possible before. Examples of materials that you can print with inkjet include plastic, glass, stainless steel, ceramic, rubber, and more.

UV printing has been used for marking metal for some time. Today, TOSTA are relying on metals to produce parts and goods because they are cost-efficient, durable, sustainable, and strong. As consumers demand stylish, sustainable drinkware, metals, especially stainless steel, have become the preferred material to fulfill this demand. Signage, industrial tools, mechanical parts, housing cases, drinkware, automotive, etc. are all industries that use metal parts.

Material

Bare metal and stainless steel

Finishes

Anodized, painted, and powder coated surfaces

Display

High quality opaque images for flat and round surfaces such as display and access panels and metal drinkware

UV ink is the most important consumable for UV printers. Choosing the wrong ink will result in poor prints. We offer three types of UV inkjet inks: the 314 series for hard and soft goods, the 160 series for flexible goods, and the 270 series for hard goods. For metal printing, we recommend the 314 UV inkjet inks and the 270 series inks. To print on metals, you will need to pair these inks with an inkjet primer to guarantee the best adhesion.

Stainless steel requires a primer for best UV ink adhesion. Stainless steel is one of the most used metals used today for drinkware because it has anti-microbial properties and does not corrode easily. Promotional products and the medical industry love using this metal. To print on stainless steel, use the M87 metal primer or the M74 primer. There is no need for flame pre-treatment. Flame pre-treatment works best on plastics. It simply increases the surface energy of the plastic.

A wipe-on primer is manually applied to the substrate using a lint-free towel. For stainless steel, the M87 primer ensures that your product will pass the scratch, tape, and wash tests. The M87 primer is a great option for stainless steel as well as powder-coated substrates, including polyester solid color-based powder coats. This primer works well with all UV inkjet inks available on the market today.

Pre-treatment paired with the correct ink will result in excellent ink adhesion. As initially discussed, ink is specific to the material of the substrate. After coating the substrate with an inkjet primer wipe, print your stainless steel or metal product with 314 UV inkjet ink for wear-resistant, high-resolution print results

Available colors for the 314 UV ink line include Cyan, Magenta, Yellow, Black, White, Light Cyan, Light Magenta, and Varnish. These colors enable decorators to achieve long-lasting, vibrant, full-color graphics on metal products, making them appropriate for cosmetic, beverage, packaging, finishing, aerospace, signage, nameplate, and industrial applications.

UV Printing Applications

Engineered Materials

Industry