Welcome to TOSTA’s Blog

The TOSTA blog aims to share the prototyping and rapid manufacturing knowledge, experience and skills we have accumulated over the years.

Electroplating Service

We provide high quality metal parts electroplating services for each client.

Electroplating Service

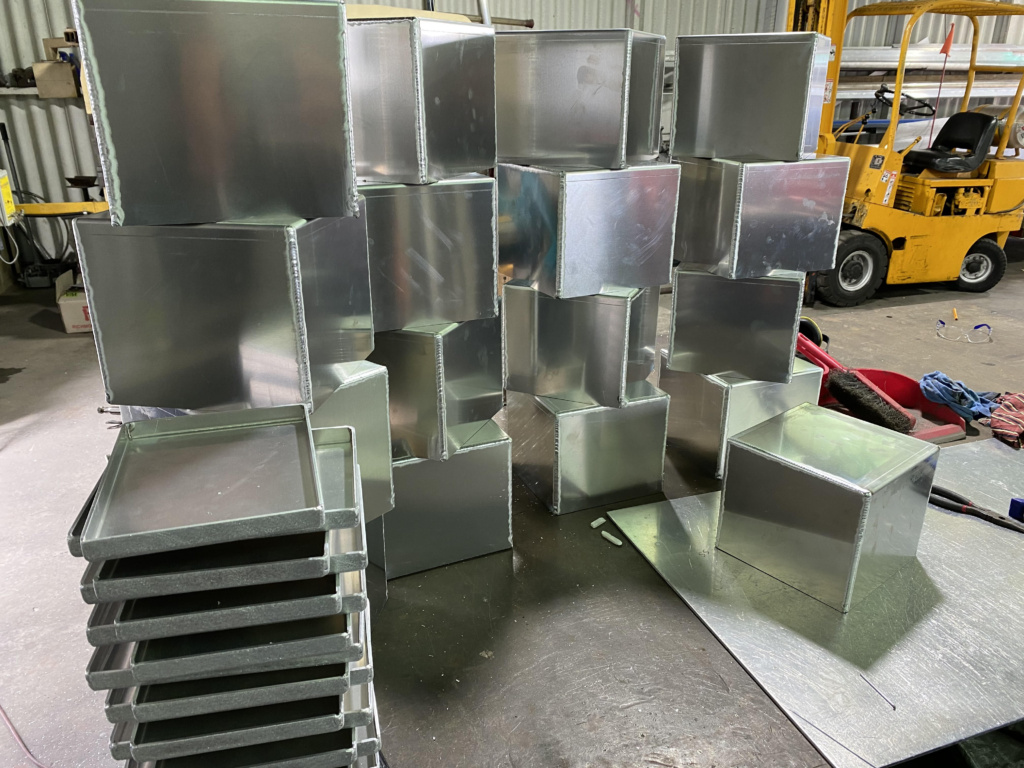

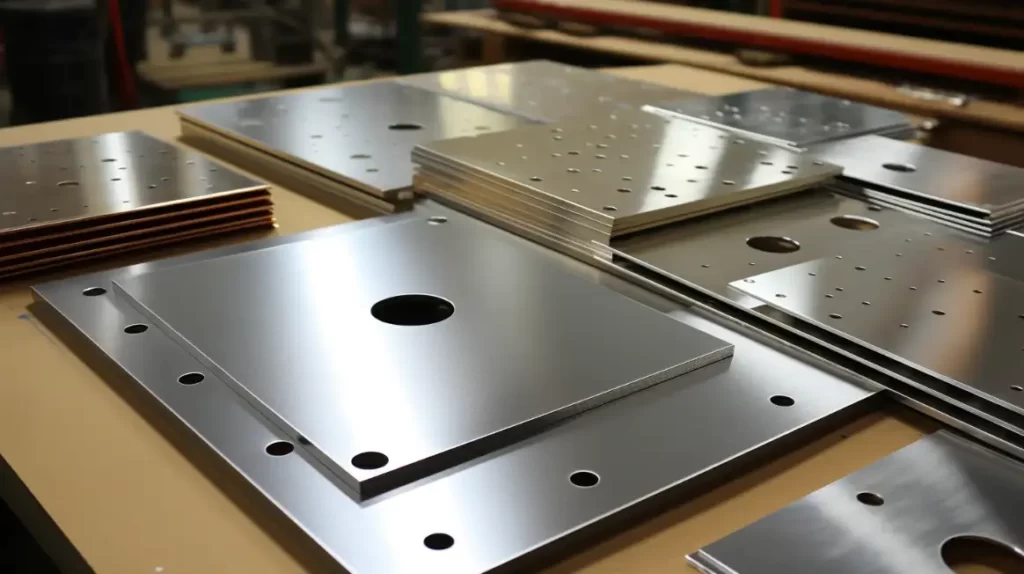

Electroplating is a surface treatment process that involves connecting an object to the negative terminal (cathode) of a direct current (DC) power source, while simultaneously connecting a metal electrode of the same metal as the desired coating to the positive terminal (anode). Metal cations in the electrolyte are reduced at the cathode surface, depositing a layer of metal on the object until the desired coating thickness is achieved. It is commonly used to enhance appearance, improve corrosion resistance, provide wear resistance, and facilitate weldability of various objects.

Electroplating is commonly used to add a decorative or protective layer to various materials such as metal, plastic, glass, and even living organisms. The process can be used to improve the appearance of an object, increase its durability, or provide it with specific physical or chemical properties, such as resistance to corrosion, wear and tear, or conductivity.

Natural metal color

Indicate masking requirements

Cosmetic by default

Electroplating is a surface treatment process that involves connecting an object to the negative terminal (cathode) of a direct current (DC) power source, while simultaneously connecting a metal electrode of the same metal as the desired coating to the positive terminal (anode).

Metal cations in the electrolyte are reduced at the cathode surface, depositing a layer of metal on the object until the desired coating thickness is achieved. It is commonly used to enhance appearance, improve corrosion resistance, provide wear resistance, and facilitate weldability of various objects.

Electroplating is commonly used to add a decorative or protective layer to various materials such as metal, plastic, glass, and even living organisms. Tin, nickel, zinc (galvanized) and chromium are common plating metals.

The process can be used to improve the appearance of an object, increase its durability, or provide it with specific physical or chemical properties, such as resistance to corrosion, wear and tear, or conductivity.

Electroplating Applications