CNC Machining

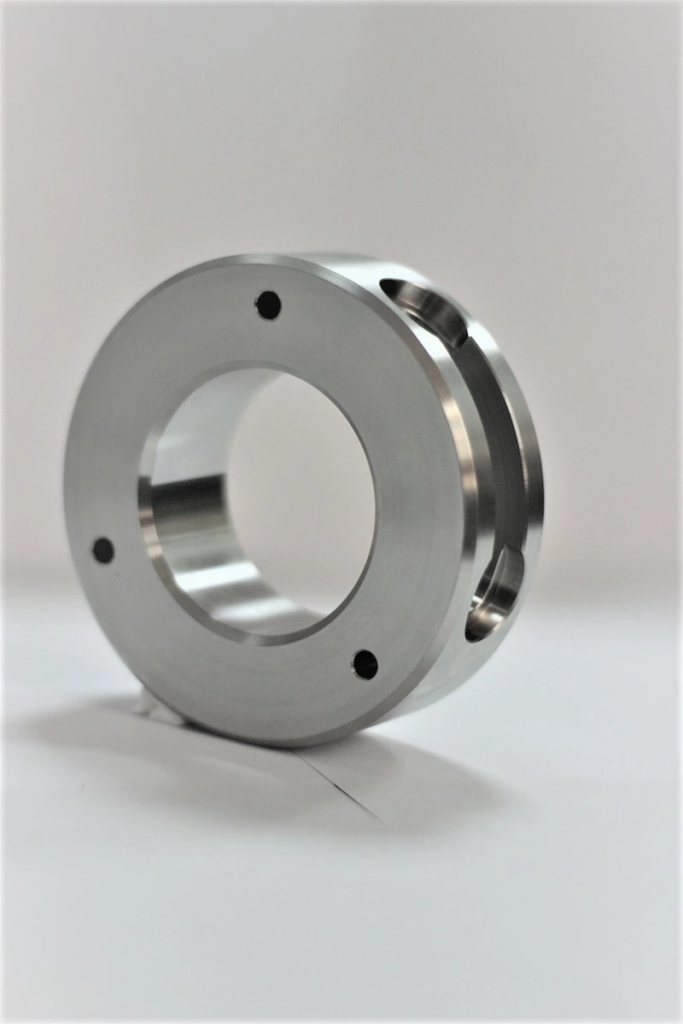

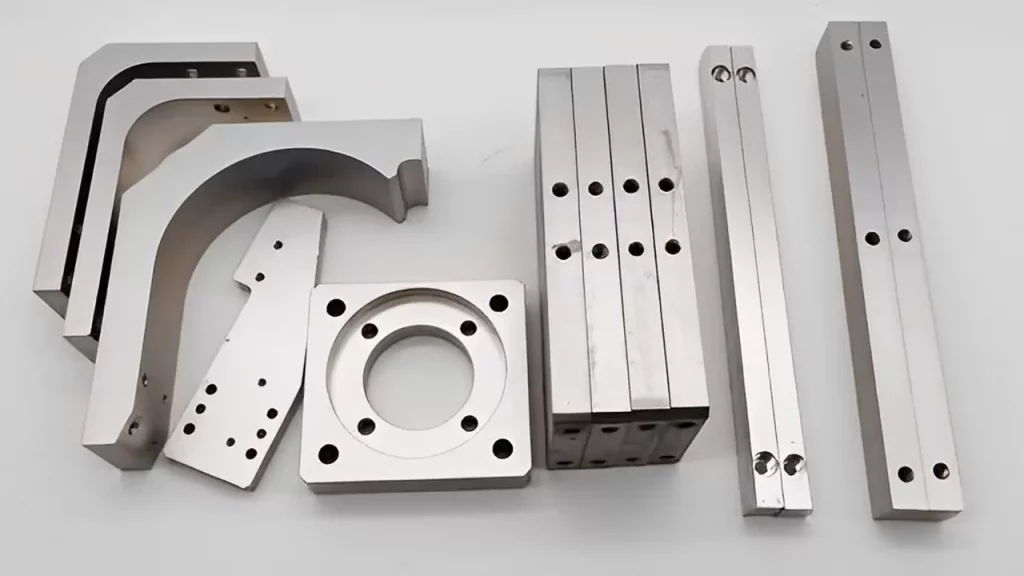

Standard CNC machines include 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers.

Affordable CNC Machining Services

With 50 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

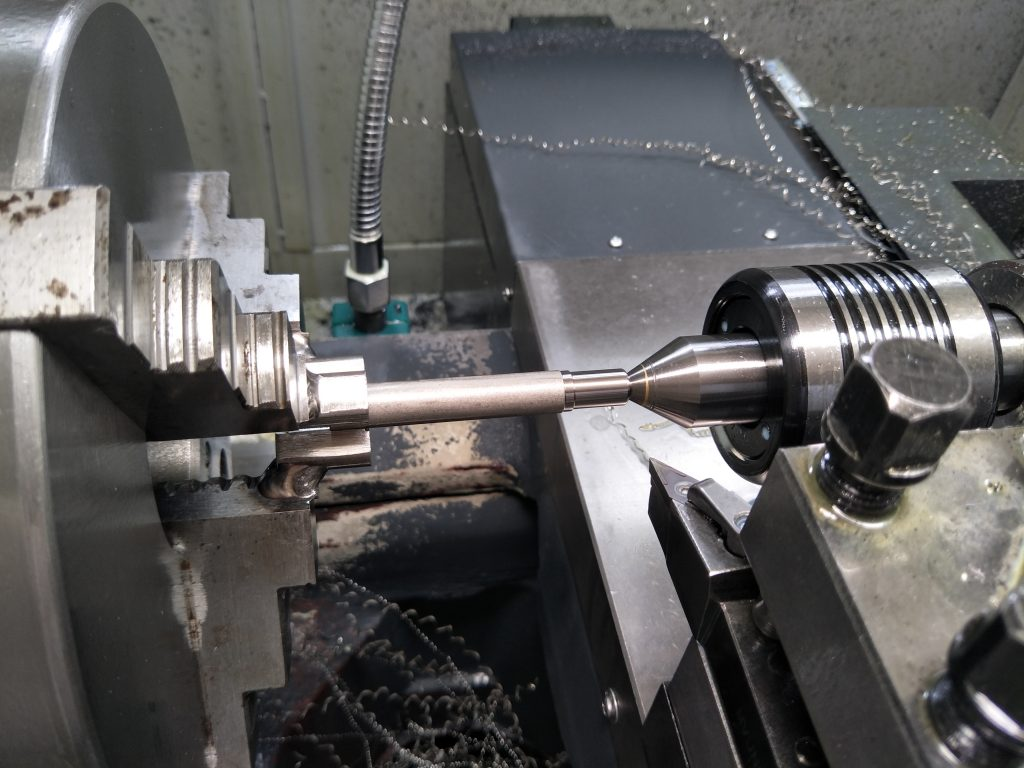

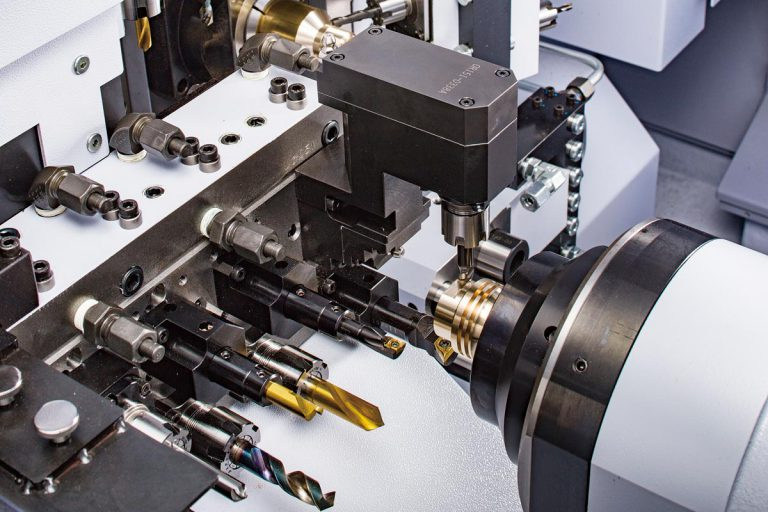

CNC turning is a more efficient method to manufacture round components from plastic and metal bars or tubes, such as worm shafts. When combined with live tooling, milled geometries can be achieved simultaneously.

If you need a super flat surface part, or round part that needs OD and ID +/- 0.005mm in tolerances, our CNC grinding machining service will be the best match of your production needs for such type of parts.

Besides standard milling service for parts in engineering plastics or metals, we also offer CNC routing service for prototypes and parts in soft materials such as EPS foam, EVA, woods.

TOSTA has many years of experience in CNC machining custom parts, from design, rapid prototyping, and part production with complex geometries to low-volume or high-volume production.

The maximum size of parts that can be processed by CNC machines is 2000mm1300mm600mm, among which the 5-axis CNC machine tool from the United States.

Haas can machine the largest parts size is 500mm500mm500mm, achieving a tolerance of +/-0.005MM, which can meet Tightest tolerances in applications such as medical,automotive, consumer electronics and aerospace.

Customized Serivces

Including CNC milling, CNC turning, EDM, wire cutting, surface grinding, lapping and CNC laser cutting

Experienced engineers

With 50+ precision 3-axis, 4-axis and 5-axis CNC machining centers, combined with other advanced capabilities and an experienced team, it can process 160+ types of metal

Fast turnaround

Our team is producing high quality machined parts according to your budget and delivery time requirements

CNC Machining Capability

3 Axis CNC Machining

3-axis CNC machining is by far the most widely used process and is often used for drilling, tapping, and cutting surfaces. 3-axis CNC machining is also the most economical and ideal for machining relatively simple parts.

4 Axis CNC Machining

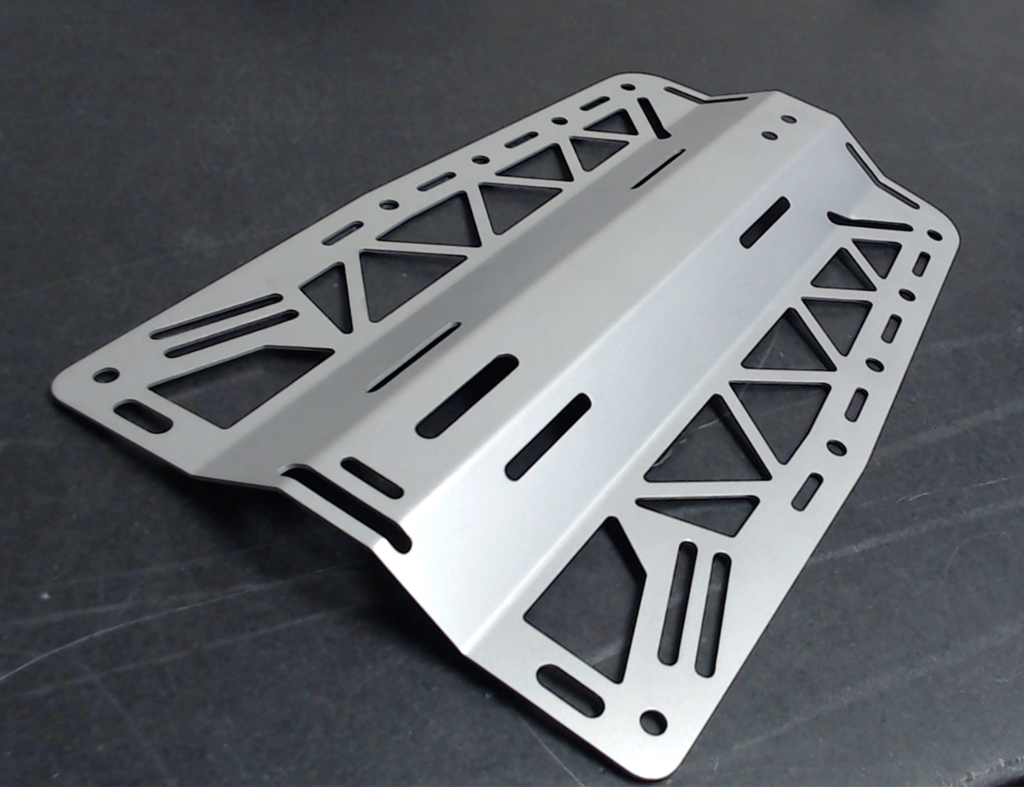

4-axis CNC machining with enhanced production capabilities. With the addition of the fourth axis, the workpiece can be turned over automatically so the machine can remove material from both sides. 4-axis CNC machining is useful when holes or cuts need to be made on the side of a workpiece.

5-axis CNC machining allows machining of all five sides of a workpiece in one operation. 5-axis CNC machining saves time and is ideal for manufacturing complex precision parts in the medical, oil and gas, and aerospace industries.

Swiss machining is a manufacturing technique designed to turn metal blanks into complex, slender or delicate components that require tight tolerances. Swiss machining accurately creates varying diameters, complex holes, hex edges, slots and threads.

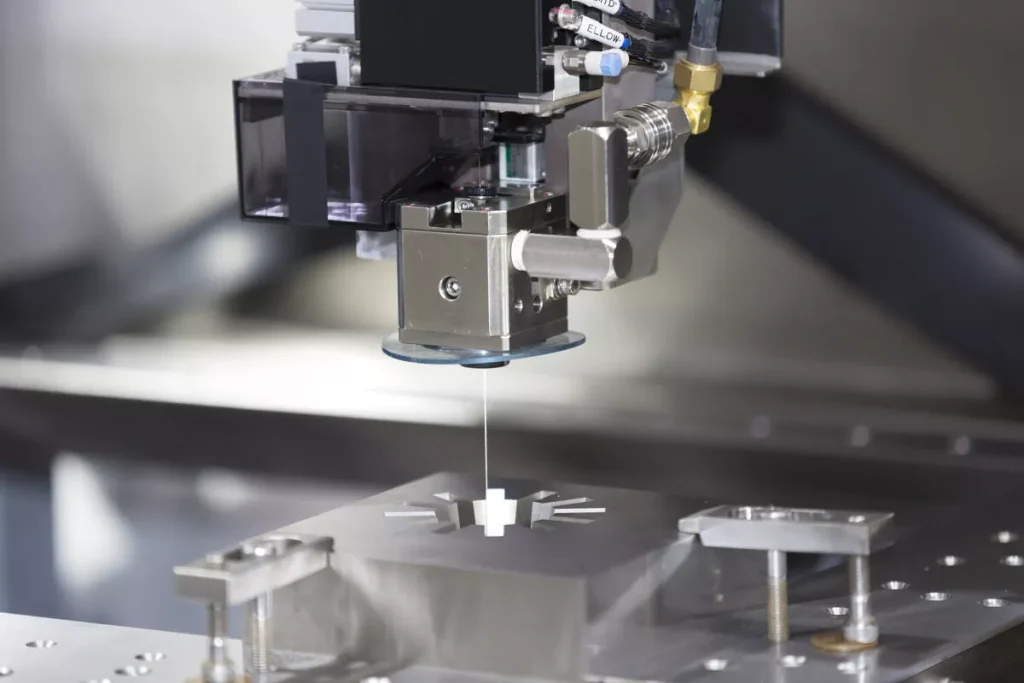

EDM

EDM, or Electrical Discharge Machining, is capable of machining complex shapes in hard metal materials. Electrical discharge machining (EDM) removes material from a workpiece using a sequence of rapid electric current discharges between electrodes immersed in a dielectric fluid.

WIR EDM

Wire EDM is an electrothermal production process that uses electrical discharges to remove material from a workpiece. It is an improvement over traditional EDM methods, is compatible with almost all conductive materials, and can create complex designs and shapes.

CNC Machining Tolerances

In TOSTA, the highest tolerance of CNC machining parts can reach 0.005mm, but not every place can achieve this precision. TOSTA’s standard tolerances apply to ISO 2768 (fine) for CNC machined metal parts and ISO 2768 (medium) for CNC machined plastic parts. Typically, we can maintain CNC machining tolerances within ±0.005″ (±0.125mm) to ±0.002″ (±0.05mm).

If you need tighter tolerances, you need a 2D drawing with complete information. Since tolerances and dimensions can be greatly affected by part geometry and material type, we strongly recommend that you consult with our engineers in advance if you have any doubts, to provide the highest possible accuracy for your part.

Linear dimension

+/- 0.025 mm

+/- 0.001 inch

Hole diameters (not reamed)

+/- 0.025 mm

+/- 0.001 inch

Shaft diameters

+/- 0.025 mm

+/- 0.001 inch

CNC Machining Materials

CNC Machining Metal Parts

TOSTA is good at CNC machining metal with any complex design structure, including turning, milling, drilling and tapping. Aluminum, magnesium alloy, zinc alloy, steel, stainless steel, copper is the conventional metal processing raw material.

CNC Machining Plastic Parts

TOSTA has excellent equipment, high performance machines, tools and fixtures for precision plastic CNC machining, and has the ability to challenge any geometric structure, high tolerances, and optical clarity.We are experts in custom plastics parts in China.

Aluminum

Aluminum is highly machinable and less expensive, making it ideal for CNC machining. Common aluminum materials are AL6061\AL7075\AL5083\AL6082.

Stainless Steel

With excellent machinability and excellent uniformity, common stainless steel materials are SU304\SU316, SU303\17-4PH\420.

Brass

Brass contains copper, zinc and other metals such as magnesium, iron and lead. Brass is highly machinable, corrosion-resistant, and ductile.

Copper

Copper parts have good machinability, ductility and impact strength. They also have electrical conductivity, corrosion resistance and wear resistance.

Titanium

Titanium has an excellent strength-to-weight ratio and corrosion resistance, and is also relatively easy to machine and weldable.

ABS

ABS is a common thermoplastic that is a low-cost solution for CNC-machined, injection-molded parts. ABS has good mechanical properties.

PA(Nylon)

Nylon is an engineering thermoplastic material with good comprehensive mechanical properties, impact resistance, excellent abrasion resistance.

PMMA(Acrylic)

Also known as acrylic or plexiglass, PMMA is a common clear thermoplastic that is used as a replacement for lightweight and shatter-resistant glass parts.

POM(Acetal / Delrin)

POM, also known as Delrin or polyoxymethylene in the industry, is a low-friction engineering plastic with impact and high temperature resistance.

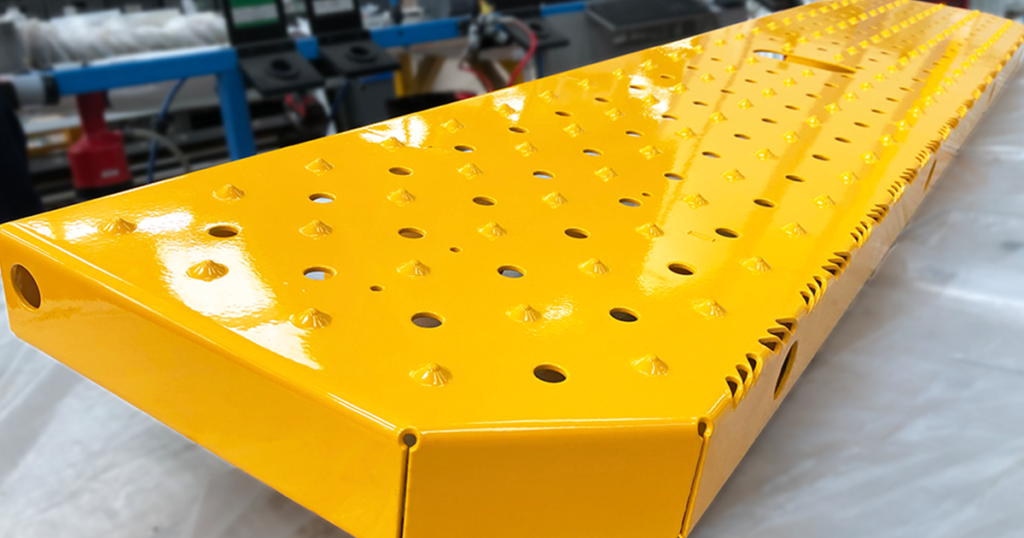

Fully Surface Finishing Service

All surface treatments available for metal parts

Powder coating uses the phenomenon of corona discharge to add a thin layer of protective polymer to the surface, ranging in thickness from about 50 μm to 150 μm.

Electroplating is a finishing process that deposits metal onto a conductive surface using many specific materials such as chromium, gold, nickel and zinc nickel.

Laser etching is a process that alters the surface of a material to create a permanent mark. Commonly used include aluminum, stainless steel, and zinc.

Sand blasting is the impact of fine abrasive glass bead particles on the part surface under high pressure, resulting in matte surface. Glass bead sizes from #80 to #220.

Why Choose TOSTA For CNC Machining

Here are the reasons why you should select 3ERP as a manufacturing partner.

With in-house advance equipment which includes HAAS CNC mills and lathes, Hexagon CMMs and Olympus XRF analyzer. We can guarantee your CNC parts are made in correct material and dimension. Our experienced engineers have built up rich, deep experience from many previous CNC machining projects in various industries.

They can handle any type of tight tolerance CNC machined parts with complex geometries. We offer consistent high-quality CNC parts that are full inspected by our quality control department when they are ready to ship out to ensure parts are built to specification and free of defects. We have enough capacity to offer fast turnaround CNC machining services, by using in-house facilities and our qualified manufacturing network.

01

Engineering Support

24/7 engineering support. Experienced engineers can provide the most suitable solution for your part design, material selection, surface treatment options.

02

Quality Guaranteed

We are an ISO 9001:2015 certified sheet metal fabrication facility and can provide material and full size inspection reports upon request.

03

Rapid Turnaround

We understand the importance of on-time delivery and expedite the production of your prototype or part.

04

Friendly Service

One-on-one support service, quick response within hours, and always pay attention to every detail of your request. You will have a great experience.

05

Great Experience

Strong comprehensive production capacity, including in-house manufacturing and surface treatment, integration of manufacturing resources.

06

Cost-effective

TOSTA is the best supplier of “Made in China” you are looking for, providing more cost-effective solutions and more competitive prices.