Welcome to TOSTA’s Blog

The TOSTA blog aims to share the prototyping and rapid manufacturing knowledge, experience and skills we have accumulated over the years.

Sandblasting Service

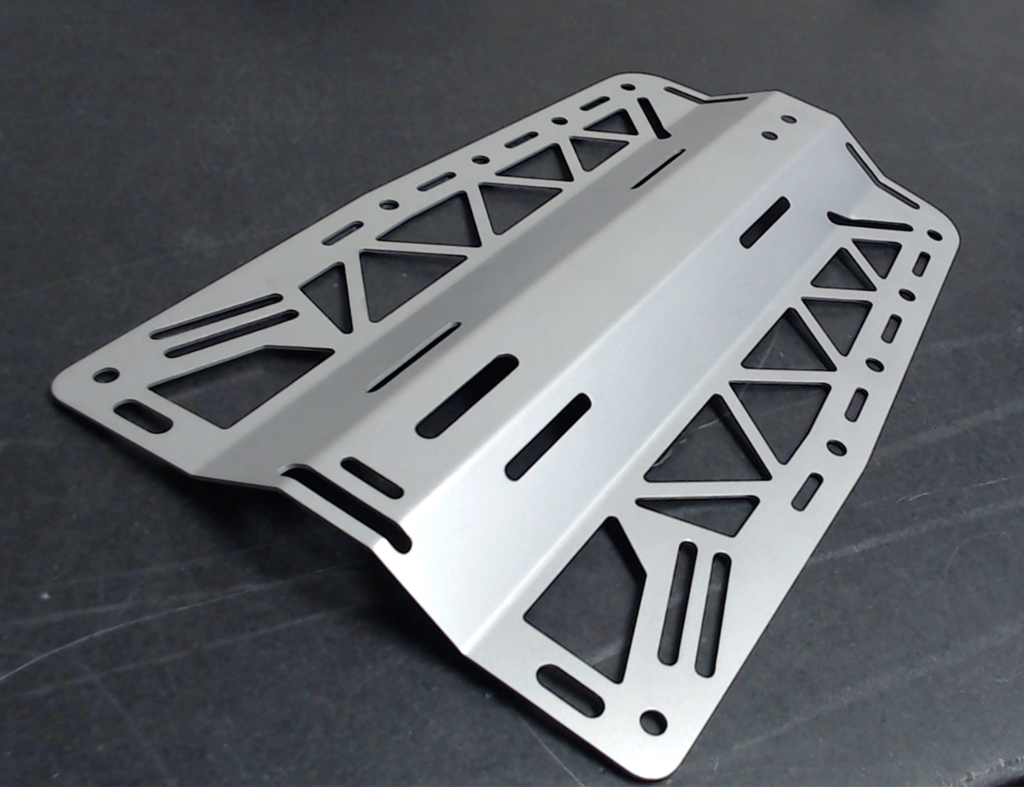

Bead blasting takes away the tool marks and gives a finished part a uniform matte or satin finish. This is mostly for looks, and it comes in different grits that show how big the bombarding pieces are. Our normal grit is #120.

Sandblasting Service

Sandblasting adds an even matte finish to machined parts, removing tool and sandpaper marks. It is the process of forcing a stream of abrasives against a surface under high pressure to roughen a smooth surface or remove surface contaminants. The size of the air pressure and the size of the glass beads are the main process parameters.

Glass beads come in different sizes from #80 to #220.

Different sizes

Glass beads come in different sizes from #80 to #220.

Color

Uniform matte of raw material color.

Cosmetic availability

Cosmetic on request

Bead blasting, also known as sandblasting or shot blasting, is a surface treatment method used to clean, smooth, or texture the surface of parts. It involves propelling fine beads or abrasive media at high speed onto the surface of the part to remove contaminants, oxide layers, burrs, or other imperfections.

The bead blasting process offers several advantages for parts surface treatment. It effectively removes surface contaminants and unwanted layers, resulting in a clean surface ready for subsequent processes like coating, painting, or inspection. Bead blasting can also create a uniform and matte finish on the part, giving it an aesthetically pleasing appearance or providing a surface texture for improved grip or adhesion.

The processing time for sandblasting service can vary depending on several factors, such as the size and complexity of the object being sandblasted, the type of abrasive material used, and the desired level of surface preparation.

For smaller objects or projects, sandblasting may only take a few hours to complete. However, for larger or more complex items, such as industrial equipment or buildings, sandblasting can take several days or even weeks to complete.

It’s best to check with the sandblasting service provider for a more accurate estimate of the processing time based on the specific requirements of your project.

Sandblasting Service

Engineered Materials

Industry