Welcome to TOSTA’s Blog

The TOSTA blog aims to share the prototyping and rapid manufacturing knowledge, experience and skills we have accumulated over the years.

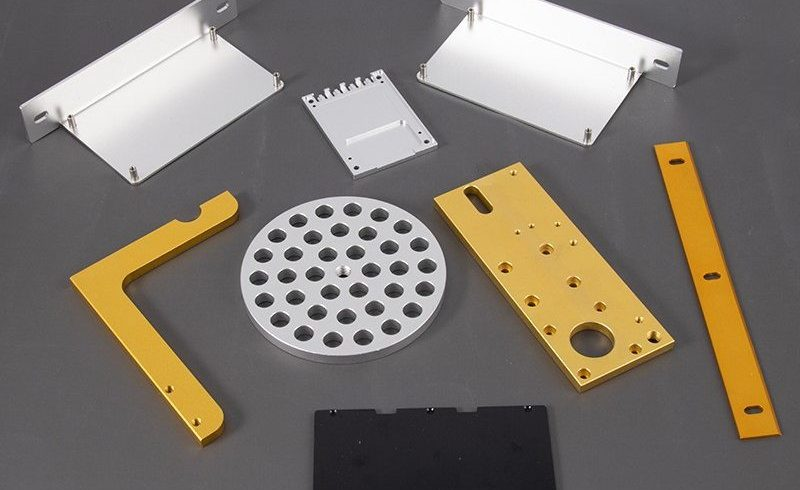

CNC Machining Service

We invest in precision 3-axis, 4-axis and 5-axis CNC Machining machines from the United States and Japan, as well as domestic automatic and manual Machining machines. AN-Prototype’s experienced team can provide you with high quality CNC milled parts.

CNC Machining Service

CNC, or computer numerical control machining, is a widely used manufacturing process that uses automated, high-speed cutting tools to remove material from a metal or plastic workpiece until the desired geometry is achieved. Standard CNC machines include 3-axis, 4-axis, and 5-axis CNC Machining machines, lathes, and routers. Machines may vary in how CNC parts are cut—the workpiece may remain in place while the tool moves, the tool may remain in place while the workpiece is rotated and moved, or both the cutting tool and workpiece may move together.

Making custom machined parts needed for nearly every industry, including automotive, robotics, medical, aerospace, electronics and industrial. TOSTA provides CNC machining services and offers custom CNC quotes on various of materials ranging from commodity aluminum, steel, stainless steel, ABS, acetal to advanced titanium, Inconel, and engineered plastics like Teflon, PPS, PEI and PEEK.

3 Axis CNC Machining

3-axis CNC Machining is the most widely used form of CNC machining, taking full advantage of the X, Y, and Z directions to create relatively simple metal or plastic parts.

4 Axis CNC Machining

4-axis CNC Machining is used to rotate the workpiece around its vertical axis. This allows machining of more complex shapes. For example milling, turning, drilling etc.

5 Axis CNC Machining

A 5-axis CNC Machining is capable of machining 5 sides of a workpiece on one machine, creating more structurally complex parts without moving the workpiece and resetting it.

TOSTA provides a custom CNC machining service to engineers, product developers, designers and more. We offer rapid prototyping, small-batch machining and high-volume production. Here are the reasons why you should select 3ERP as a manufacturing partner.

With in-house advance equipment which includes HAAS CNC mills and lathes, Hexagon CMMs and Olympus XRF analyzer. We can guarantee your CNC parts are made in correct material and dimension.

Our experienced engineers have built up rich, deep experience from many previous CNC machining projects in various industries. They can handle any type of tight tolerance CNC machined parts with complex geometries.

We offer consistent high-quality CNC parts that are full inspected by our quality control department when they are ready to ship out to ensure parts are built to specification and free of defects. We have enough capacity to offer fast turnaround CNC machining services, by using in-house facilities and our qualified manufacturing network.

Your CNC Machining project will be handled smoothly with our in-house CNC machining department and supplier network. TOSTA provides a complete, fast turnkey solution for your next CNC project. So you can focus on bringing your product to market.

CNC Machining Applications

CNC Machining Parts