Sheet Metal Fabrication

Sheet metal fabrication is a valuable production method for creating functional components such as panels, brackets and enclosures.

Affordable Sheet Metal Fabrication Services

Laser sheet metal fabrication or laser sheet cutting has been successfully used in various industries and refers to the process of cutting metal material into desired shapes using a high power density laser beam.

The sheet metal bending process involves passing a sheet of metal through a wedge-shaped tool (cutter) to apply pressure, push it into a V-shaped opening and bend the sheet to the desired angle.

Sheet metal stamping (also known as sheet metal pressing and forming) is the process of pressing flat metal in coil form through dies to form parts of the desired shape.

Sheet metal welding refers to the process of joining heated and melted sheet metal parts together to increase their strength or create a single integrated product.

Tolerance

Sheet Metal Fabrication Standards

Edge to edge

+/- 0.127 mm

+/- 0.005 in.

Hole to hole

+/- 0.127 mm

+/- 0.005 in.

Edge to feature

+/- 0.762 mm

+/- 0.030 in.

Edge to hole

+/- 0.127 mm

+/- 0.005 in.

Bend to edge

+/- 0.254 mm

+/- 0.010 in.

Over formed part

+/- 0.762 mm

+/- 0.030 in.

Available Sheet Metal Fabrication Materials

Steel

Steel 1018

Steel 1045

Steel A569

Steel A36

Steel

Steel A366/1008

AZ55

A653

1095 Spring Steel

Stainless Steel

Stainless steel 301

Stainless steel 304

Stainless steel 316/316L

Aluminum

Aluminum 1100

Aluminum 5052

Aluminum 6061

Copper

Copper 101

Copper C110

Copper 260

Bronze

Bronze 220

Bronze 510

Titanium

Titanium (Grade 2)

Titanium 6AI-4V (Grade 5)

Nickel Alloys

Inconel 625

Nickel Alloy 200

Nickel Alloy 400

Finishing Services

Surface Treatment of Sheet Metal Parts

Powder Coating

Powder coating is a free-flowing dry powder that is electrostatically coated on the surface and then cured by heat or ultraviolet light.

Anodizing

Anodizing can improve the corrosion resistance, wear resistance and hardness of aluminum parts and protect the surface.

Polishing

Polishing is the process of creating a smooth, shiny surface through physical friction or chemical interference.

Electroplating

Plating can be functional, decorative or related to corrosion protection, with chrome and nickel plating of steel auto parts being common.

Trusted Metal Fabrication Company

Why Choose TOSTA For Sheet Metal Fabrication

TOSTA, custom sheet metal prototyping services offer a fast and cost-effective solution for your projects.

Services including bending, punching, cutting standard gauge metal for both prototypes and production runs.

Sheet metal fabrication produces durable, end-use metal parts with a wide selection of materials and finishes that meet your specifications, for a variety of industries like: Automotive, Medical device, Aerospace, electronics, energy and robotics.

01

Engineering Support

24/7 engineering support. Experienced engineers can provide the most suitable solution for your part design, material selection, surface treatment options.

02

Quality Guaranteed

We are an ISO 9001:2015 certified sheet metal fabrication facility and can provide material and full size inspection reports upon request.

03

Rapid Turnaround

We understand the importance of on-time delivery and expedite the production of your prototype or part.

04

Friendly Service

One-on-one support service, quick response within hours, and always pay attention to every detail of your request. You will have a great experience.

05

Great Experience

Strong comprehensive production capacity, including in-house manufacturing and surface treatment, integration of manufacturing resources.

06

Cost-effective

TOSTA is the best supplier of “Made in China” you are looking for, providing more cost-effective solutions and more competitive prices.

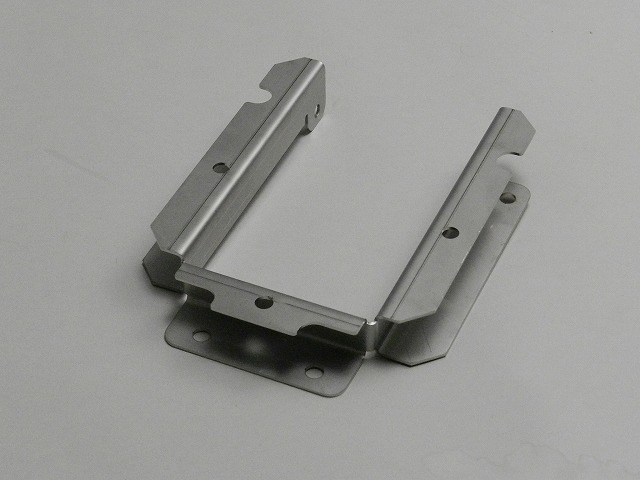

Gallery of Sheet Metal Fabrication Parts

For many years, we have been providing various sheet metal processing prototypes and mass production.

Below are the sheet metal fabrication parts we made earlier.