Quality Inspection

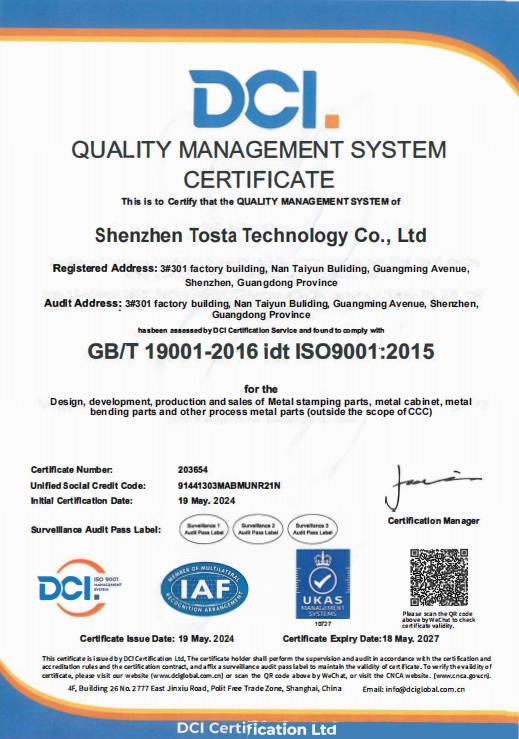

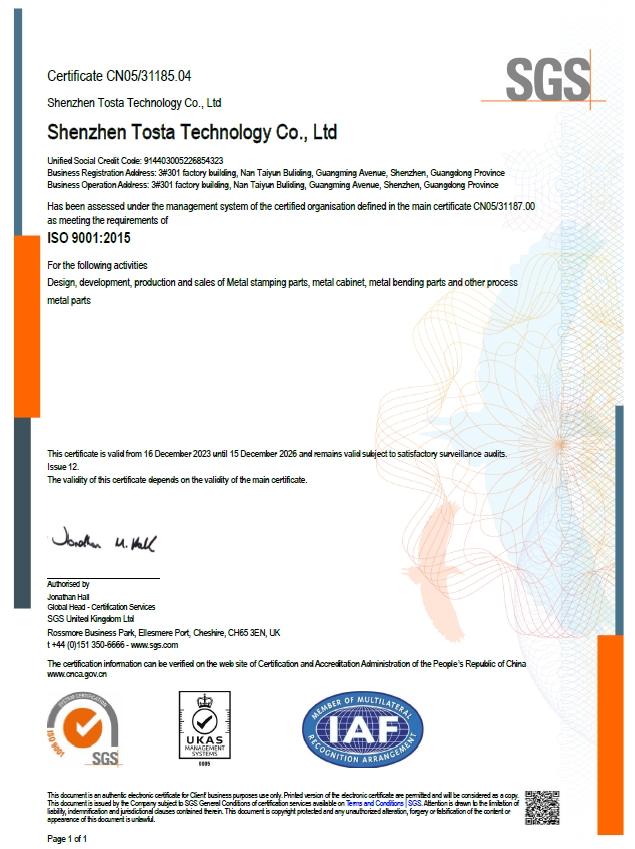

TOSTA’s Quality Management System has been approved and certified to the ISO 9001:2015 standard.

How To Ensure Excellent Quality

Pre-manufacturing

Technology Assessment

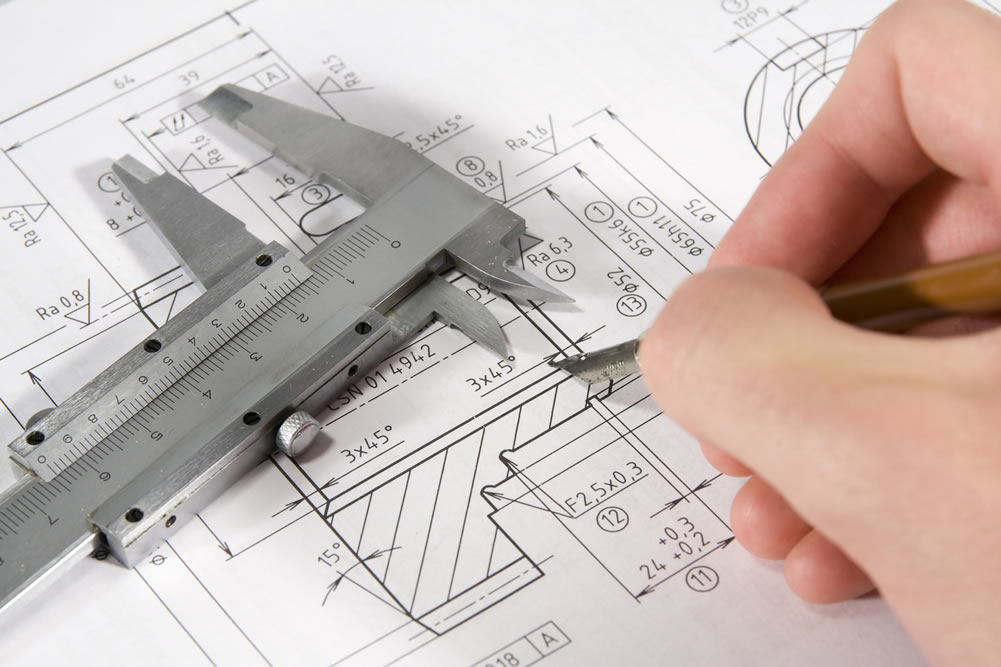

Our engineering team performs a technical evaluation of your part design before the production phase begins. This includes the evaluation of important factors such as materials, surface finish, structure, workmanship and other details of 3D and 2D drawings.

Material Verification

Upon request from our customers, we provide certification of the materials used to manufacture your parts. The report is from the raw material manufacturer and usually includes material calorific value, material grade, material size, mechanical properties, chemical analysis, etc.

Manufacturing

On-site inspection system

In precision machining, it is important that the material being machined is always in the correct position. There is an on-site inspection system to automatically check the position and make corresponding adjustments. Using an on-site inspection system further helps to avoid early problems, saving cost and time.

Process Quality Control

At Tosta, we strictly adhere to ISO9001:2015 requirements. Every 2 hours, quality control personnel conduct routine inspections of all parts being produced. This further prevents the occurrence of risks.

Manufactured

Full size inspection report

For all orders, we can provide a full size inspection report upon request. The report will include the following: part count, critical dimensions, threads and tolerances, thickness and depth, part appearance, etc.

Package

It is important to ensure that the parts we manufacture are of the highest quality. We know the unpredictability of logistics. Therefore, we ensure that the risk of the parts is reduced during the packaging process. Four layers of protection are used in the packaging process: 1. Wrapping paper 2. Pearl cotton 3. Foam 4. Paper/wooden box, to ensure that we provide you with the best quality and most beautiful parts.

TOSTA is committed to continuous improvement and optimization of all custom manufacturing capabilities from prototype to production, and corresponding quality control processes, including sheet metal manufacturing, CNC machining, rapid prototyping and rapid tooling,etc.

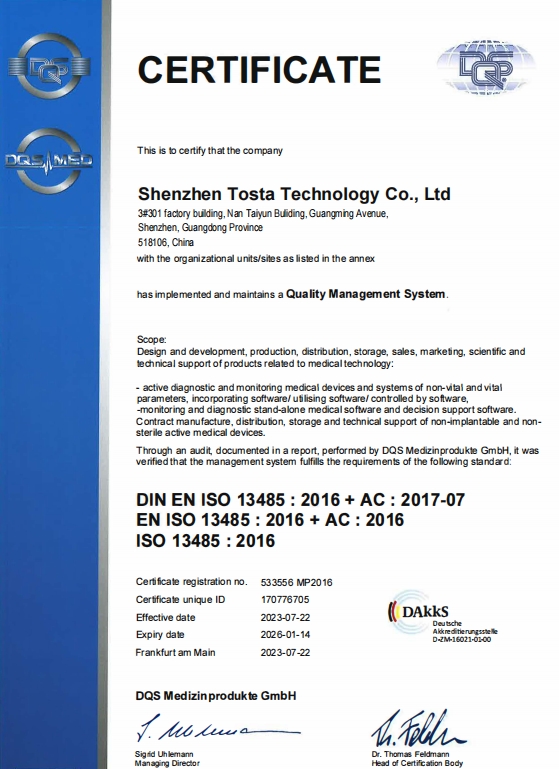

We strictly follow the ISO 9001&ISO13485 certified quality management system, based on a series of standardized production procedures and work instructions, and use advanced testing equipment to measure and inspect each production step to ensure that your project meets strict quality specifications.t each production step to ensure that your project meets strict quality specifications.

Quality Assurance For Manufacturing Parts

High-Quality Materials

We attach great importance to the quality of the materials used. Every batch of material that arrives goes through a rigorous testing process that allows us to differentiate high quality material from low quality material.

Professional Project Engineer

Our team of professional project engineers is dedicated to reviewing and optimizing your 3D drawings. They have the expertise and expertise to assess the feasibility of your design and determine the most efficient methods for creating final prototypes and production parts.

Strict Quality Inspection

Our dedicated Quality Control (QC) staff conduct a comprehensive series of inspections, including material inspections, processing inspections and finished product inspections, and provide full size reports.

State-of-the-art inspection facilities

To ensure the accurate satisfaction of quality requirements, AN-TOSTA invests heavily in its inspection department to introduce a series of advanced testing equipment, including Hexagon coordinate measuring machine, PolyMax Gun,XRF Analyzer,Smart Scope Zip Lite 300,height caliper, micrometer, plug gauge, etc, with the measurement accuracy up to ±0.02μm.

Our guarantee to quality system includes that efforts are made to implement the quality inspection in each and every process, and that experienced inspectors may use reliable and comprehensive detection means and inspection standards. The parts of TOSTA are respected by satisfying the rising demands of customers.

Coordinate Measuring Machine

Leitz PMA coordinate measuring machine not only collects data rapidly, but also has a high measuring accuracy and the ability to detect the pieces in complex shapes. Leitz PMM-C has become the universal measurement center in the true sense, with the maximum measuring accuracy of 0.02μm.

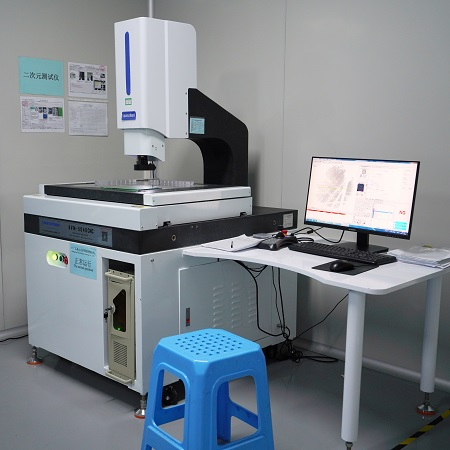

Two-dimension image measuring instrument

The device can quickly read the displacement value of the optical length, and establish a spatial geometric structure on the basis of the obtained torque result through the operation of the software module; and generate graphics on the screen for the operator.

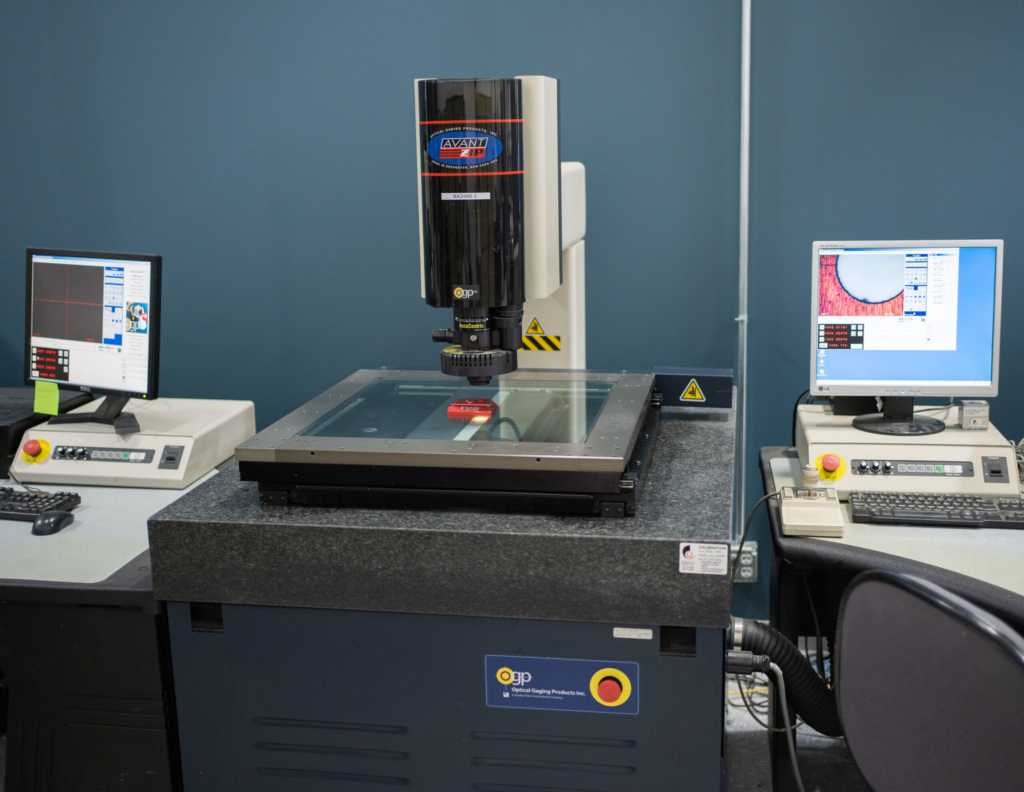

Smart Scope Zip Lite 300

The SmartScope ZIP Lite 300 is a non-contact optical measuring system using a high intensity white LED light for fast 2D measurements of parts. High-precision mechanical bearings and DC stepper motors, mounted to a solid granite base, ensure reliable and repeatable precision.

XRF Analyzer

X-Ray Fluorescence (XRF) analysis is a non-destructive testing (NDT) process by which materials such as metals, clothes, plastics, ceramics, etc. are exposed to low level, short-wave X-rays or gamma radiation. The XRF analyzer can also detect banned materials under the REACH and RoHS legislation.

PolyMax Gun

This device uses a beam of laser light to bounce off the surface of a test sample and read the unique signature given off by its molecular vibration. It contains a database of hundreds of plastic types in memory, and can be programmed with additional plastic types whenever the need arises

Plug Gauge

As the essential instrument for the standardized testing of holes, plug gauge may be not only used to check the position, measure the size of holes, or inspect the distance between holes, but also used as stop-pass gauge and to measure the depth of holes.

Why Choose TOSTA

TOSTA provides integrated parts finishing services to meet your diverse needs, and try our best to ensure the color, texture, gloss and surface finish of the parts and exceed your expectations. Please contact us to learn more about how we can assist you with the part finishing process described below.

01

Engineering Support

24/7 engineering support. Experienced engineers can provide the most suitable solution for your part design, material selection, surface treatment options.

02

Quality Guaranteed

We are an ISO 9001:2015 certified sheet metal fabrication facility and can provide material and full size inspection reports upon request.

03

Rapid Turnaround

We understand the importance of on-time delivery and expedite the production of your prototype or part.

04

Friendly Service

One-on-one support service, quick response within hours, and always pay attention to every detail of your request. You will have a great experience.

05

Great Experience

Strong comprehensive production capacity, including in-house manufacturing and surface treatment, integration of manufacturing resources.

06

Cost-effective

TOSTA is the best supplier of “Made in China” you are looking for, providing more cost-effective solutions and more competitive prices.

ISO Certifications

We go to great lengths to ensure our manufacturing meets the highest industry standards. To demonstrate our commitment to quality and excellence, we actively seek and obtain accredited certifications from reputable organisations.